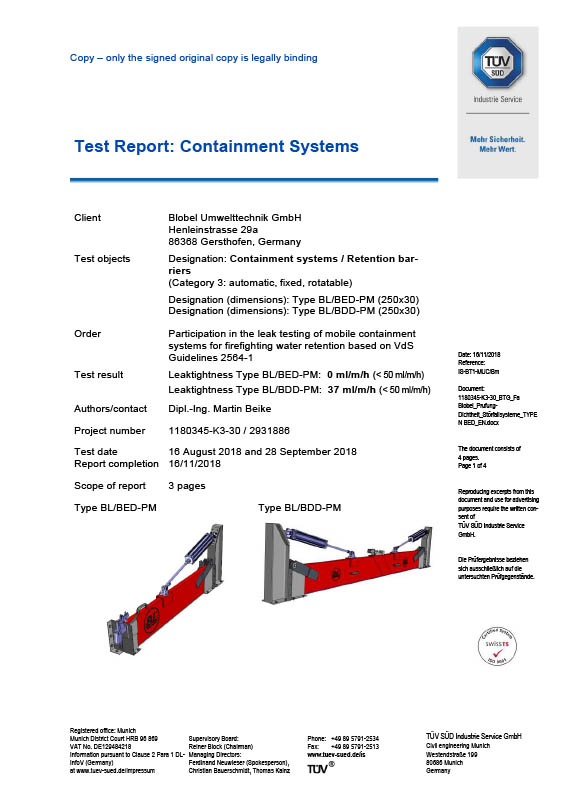

Over the past 24 months, TÜV SÜD's experts have been guests at BLOBEL several times. On a test stand specially built for this purpose, automatic, manually insertable and manually rotatable models of the worldwide known BLOBEL containment systems proved their reliable leak tightness.

Following chapter 5.8 of the VDS guideline 2564-1, the TÜV testers confirmed that the refined, even more chemical-resistant and more flexible BLOBEL special seal meets all requirements and ensures safe retention of environmentally hazardous extinguishing media in the event of a emergency. TÜV-tested quality, Made in Germany.

The latest certificates can be downloaded from the individual models:

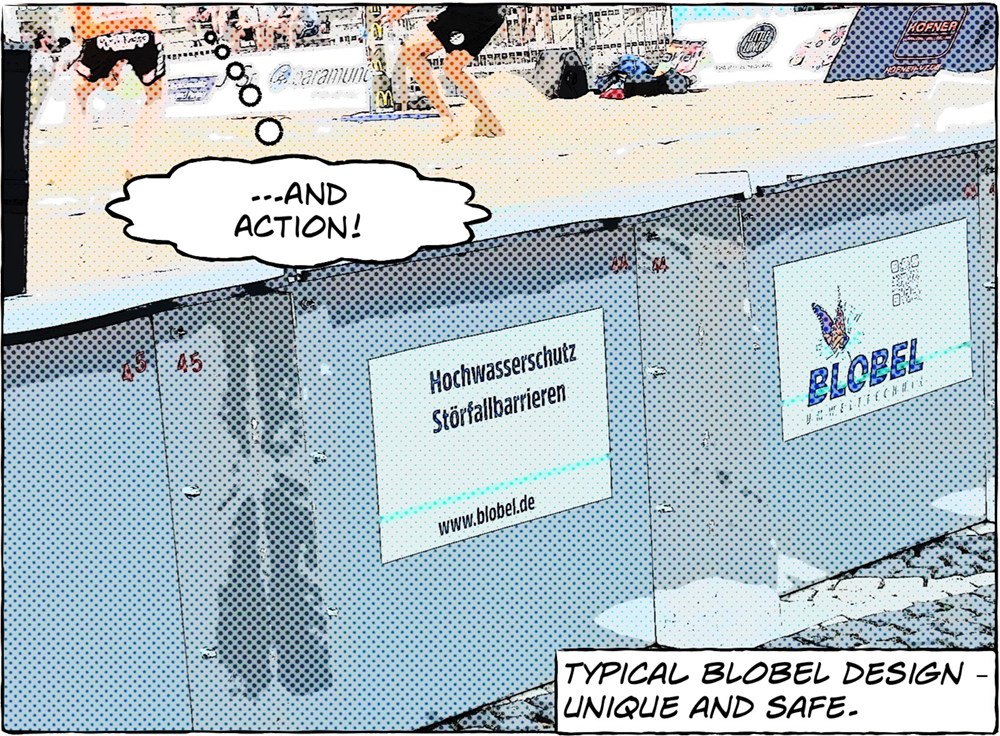

BLOBEL Umwelttechnik built and sponsored Beach Volleyball perimeters in 2016 for the Bavarian Championship and now we have done it.again in 2018.

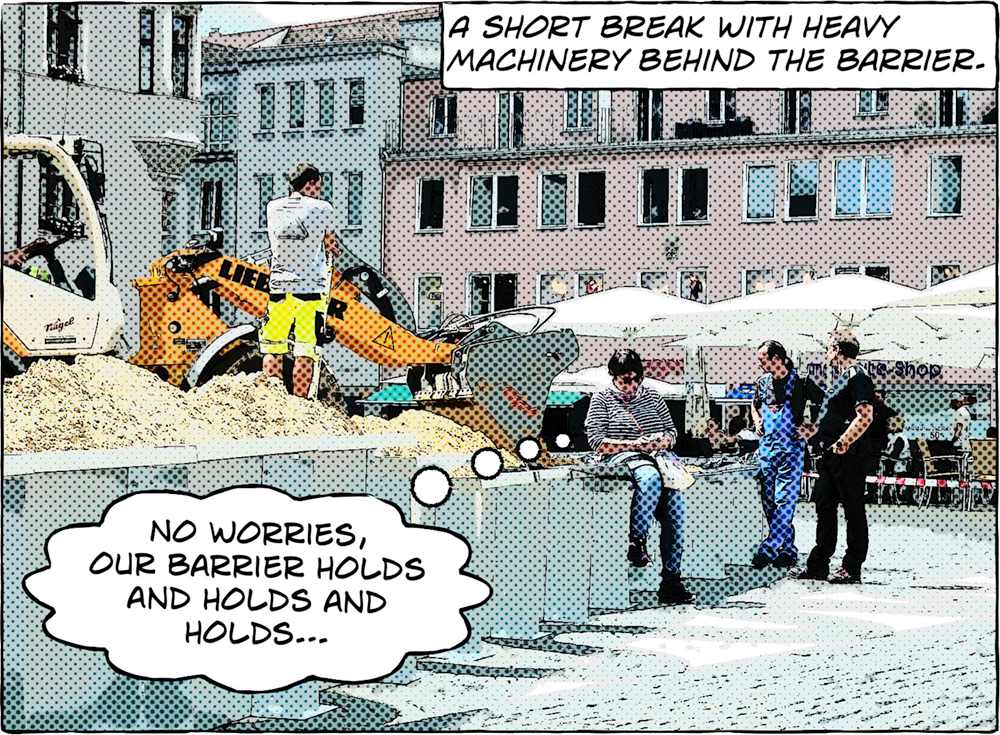

The venue is the town square in Augsburg. This is a big challenge, as the whole area is uneven and sloping. This year Blobel has created a completely new design, which is very stable and reuseable. In the end the modular system has to withstand the pressure of tons of sand and heavy machinery. Now we can look back on over 25 years of experience and expertise in the event of flooding and spillage.

Blobel Umwelttechnik is based in Gersthofen and is delighted, to support this local sporting event.

Celebrations marking Blobel GmbH’s 25th anniversary had only just ended – along with the training courses held every year for the staff at our various representative offices – when things got into full swing again.

Next on the agenda was the Bavarian Beach Volleyball Championship – where Blobel was able to make an important sponsorship contribution by providing Blobel barriers to enclose the sand court. The idea for this was suggested by the managing committee of the organizing club: the DJK Augsburg Hochzoll e.V.

What made this event special was the venue: the tournament was to be held on Augsburg’s main square, right in front of the town hall.

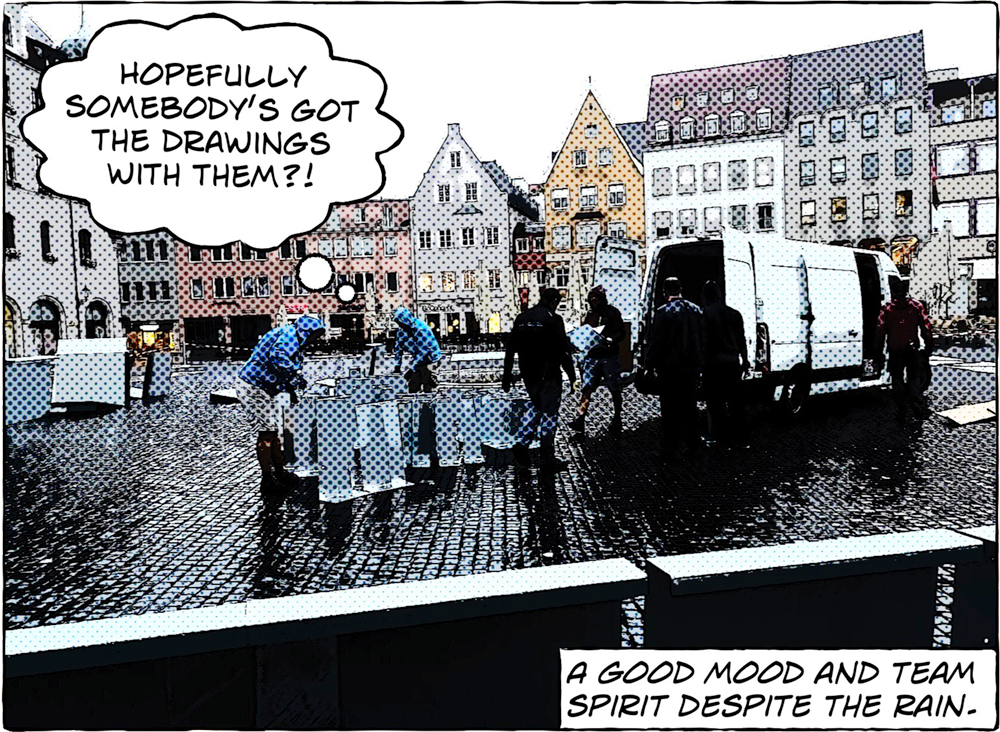

The general conditions proved to be a real challenge:

- the cobblestones were not to be damaged

- the ground was uneven and had a noticeable slope

- building the court and stands had to be coordinated with the deliveries of sand

- the barriers framing the sand court had to keep many tons of sand in place

- dismantling the court and stands required as much coordination as their construction

And so a great deal of effort went into the planning, drawings and calculations. The choice fell on Blobel containment profiles and liquistop barriers. Work began on 23 July 2016. The modules were delivered by our manufacturing partner Müllers GmbH in Rohrenfels. First of all, our joint, four-man team of design engineers and fitters built up the enclosure at the designated location in order to precisely position the corner posts. Then most of the barriers had to be taken down again to enable a huge plastic sheet to be spread out across the entire area so that the trucks waiting in line could unload the sand onto it. A bulldozer was used to spread and compress the sand. The movement and weight of the sand made it necessary to provide additional support for the barriers lining the long sides of the court. The barriers went up step by step after each load of sand that had been spread, until the “sandpit” could be closed off. It was arduous and sweaty work in the blazing sun. The following day, the heat forced our second team to put in a late-night shift: the barriers had become so hot during the day that they warped the advertising banners, making it impossible to glue them to the barriers. Thanks to the personal commitment and active assistance of a number of hard-working relatives, that, too, was overcome. The court was now finally ready for play and the tournament could get underway.

We stayed on in the stands as spectators to cheer on the players and applaud their artistry. And of course we were delighted to receive praise from the event organizers for having successfully enclosed the volleyball court.

It was an interesting experience, one that enabled us to demonstrate the quality of our barriers in what was a rather unusual setting. This foray into the world of sport is a perfect example of our company motto: The right Blobel barrier for every situation!

Back at Blobel, we’re now back to providing individual solutions in the field of flood protection and containment systems.

Click on the picture to start the video (approx. 14 MB).

As the owner of BLOBEL Environmental Engineering LLC, Delaware, USA, Norbert Blobel coordinated and oversaw the installation of our biggest joint contract to date: a total of 94 fully automatic BLOBEL barriers (90 BDD-U-PM for loading ramps and 4 BED-PM), along with 16 semi-automatic barriers provided by the company GSB.

Unfortunately, he didn’t receive a kilometre allowance, which would have been really worthwhile, for there were days when he covered up to 15 kilometres moving between the various construction areas inside the huge Bayer HealthCare warehouse (600 x 182 metres) in Georgia. It’s just as well that he’s an active ultra marathon runner.

Installing the barriers took from May to September 2015 – and only minimally affected the ongoing logistical operations at this distribution centre.

BLOBEL Umwelttechnik GmbH acted as contractor for BLOBEL Environmental Engineering LLC, which in turn had been commissioned by ARCO Design/Build, Inc., USA. We were able to complete this enormous project on time and on budget. A superb achievement by everyone involved – from ‘BLOBEL Deutschland’ and ‘BLOBEL USA’.

Click on the photo to start the video (approx. 10 MB).

The 18th of March 2015 was an exciting day for the company staff and management at Blobel Umwelttechnik GmbH. A few days earlier, the European Flood Protection Association had delivered a test container and installed it in the construction hall, and had also set up the test stands in the hall. Now the time had come to conduct the actual testing of three Blobel flood protection systems.

Due for testing were a window barrier in Category 03 (Object Protection: Windows) and two slide-insert barriers without supports for manual montage in Category 01 (Object Protection: Gates). A divided version of the slide-insert barriers with a central support/double support post was also tested in Category L (Landscape Protection). In addition to the experts from the European Flood Protection Association, Blobel had also arranged for a TÜV Süd inspector to be present. Extensive documentation on the barriers was submitted prior to the testing.

Inside the association’s specially designed container are test stands of various dimensions, which provide the framework for the barrier tests. The barriers have to be assembled and locked into position inside the test stand under conditions simulating a real emergency – while the inspectors clock the time required to do so. Water is then pumped to a certain height into the space between the wall of the test stand and the barriers. At specified intervals, the inspectors measure and log any leakage to within a millilitre.

Aside from the time taken to assemble and dismantle the barriers, and the watertightness of the flood protection system, the evaluation process also takes into account the storage and transportation volumes of the barriers. The European Flood Protection Association allows for various leakage tolerances, ranging from Class 0 to Class 5.

A flood protection system designated as Class 0 shows no leakage, whereas a Class 1 system leaks up to half a litre per square metre per minute. Class 2 permits leakage of between half a litre and 1 litre. The leakage rate for Class 3 is between 1 and 5 litres. For Class 4, it is between 5 and 10 litres. Finally, Class 5 describes barriers that leak more than 10 litres per square metre per minute.

Test Results:

- In Category 01 (Object Protection: Gates), both flood barrier systems with no central support/double support post – BL362 HDS (200x50) and BL324 HAP-SB (200x50) – were rated as Class 1.

- In Category L (Landscape Protection), the Blobel barrier BL329 HAP-SB (150x80) with a central support/double support post was also rated as Class 1.

- Also in Category L, the Blobel flood protection system BL361 HDS (150x80) with a central support/double support post was rated as Class 2.

- SAnd in Category 03 (Object Protection: Windows), Blobel’s window barrier plate BL341 FAP-PR 1 was even rated as Class 0.

New inspection dates have already been set for other barrier types.

The largest construction industry fair for the Pacific Region, Central America and the Caribbean was held for the 13th time in Colombia. It covers virtually everything, from civil and structural engineering, architecture, urban development and design to interior decoration and furniture.

BLOBEL was represented in Bogotá for the first time, at a shared Bavarian stand that was part of the German stand organised by the Chamber of Foreign Trade. We have been receiving more and more inquiries about flood barriers from this part of the world and are currently installing a number of BLOBEL containment barriers in Medellín – so the fair was a welcome opportunity to get better acquainted with this new market.

For six days, a steady flow of visitors streamed through the halls from 10 a.m. until 8 p.m. It was a long and busy week, but worth it for the remarkable interest shown and the high quality of the contacts made. We were able, for example, to hold promising technical discussions about our containment and flood protection systems with a good many engineers and staff members from various planning offices.

The expanded and renovated hall complex of the Mainfrankensäle in Veitshöchheim lies directly on the Main River – which of course makes flood protection an extremely important issue.

More than 10 BLOBEL flood barriers (BL/HDS model) are already in place to ensure that the many events held here – such as the televised carnival centrepiece ‘Fastnacht der Franken’ – and the visitors who attend them are not put at risk by flood water. Side supports for the flood barriers were fitted to single and double-leaf doors and to lift doors before the shell of the building was completed.

When these lateral supports were installed, there was no flooring to attach them to as the ground consisted merely of a layer of gravel. Special substructures of V2A stainless steel were therefore put into place, with floor brackets that would lie flush with the floors when these were finally laid down.

If it comes to an emergency, the special seal applied to the lowest barrier element inserted into the side supports will press down onto these floor brackets. Together with the floor brackets, the tightly locked closure elements and the U-shaped, stainless-steel side posts (also fitted with a special seal) thus form a watertight space that closes off on three sides in the event of flooding.

Image 1: Shell construction – If flooding is imminent, the flood barriers can be inserted by hand into the side supports. The vertical locking mechanism presses the barriers down onto the special sealing material applied below to form a watertight seal.

Image 2: The lateral guide rails were put in place before the flooring was laid down, so a substructure with stainless-steel floor brackets was needed that would later be flush with the surface of the floor and provide an optimum base onto which to compress the sealing material applied to the bottom barrier.

Download the article on the Mainfrankensäle from Architektur Premium.

The first national conference on the civil defence of São Paulo – 1. Conferência Estadual de Proteção e Defesa Civil de São Paulo – was held in Brazil on April 13 and 14. Representing BLOBEL at our company stand, which was equipped with two types of barriers, our Portuguese-language brochures and our trade fair film, was Silvia Kühl. She was able to talk to many of the conference participants, who showed considerable interest in our products. Demand for more information material was equally strong. It’s clear that the Brazilian civil defence experts were highly impressed by the design and quality of our barriers. Thanks to the new contacts made, our participation at two further trade fairs in Brazil was also discussed. We’re delighted with this positive response, and we thank Silvia for the competent support she provided.

The fact that people in Salzburg were able to take a relatively relaxed view of the flood situation in the spring of 2013 – and keep their feet dry as well – was due not least of all to the BLOBEL flood barriers, which provided effective protection in critical areas. Along the Elisabethkai promenade, for example, and in the city’s Josephiau district, passersby and local residents were able to gaze in amazement, with no risk to themselves or their property, at the mass of mud and water flowing past them down the River Salzach.

The trade fair in São Paulo was very well attended, and the same can be said of our booth. Once again, the focus of interest was primarily on flood protection, drawing visitors not only from São Paulo and surrounding areas, but also from further afield – in fact, some of the visitors who travelled from other federal states, such as from Manaus, capital of the state of Amazonas, had to cross up to two time zones to take part in the fair.

AThe Blobel stand was also able to welcome and advise interested parties from neighbouring Paraguay, Uruguay and Peru. What makes it worth our while to keep participating in this very costly and organisationally demanding trade show in Brazil are the promising contacts we make there.

We would like to extend a particularly warm welcome to Silvia Kühl, our newly acquired representante no Brasil, and look forward to a close and successful cooperation.

The dam that protects Kurtinig from the River Adige broke some years ago, with the result that parts of the village and the nearby town of Salurn fell victim to flooding. Flood simulation has now shown that the Bahntrasse could serve equally well as a dam if only the road’s underpass were not a perfect conduit for a mass of water to flood into the village.

This prompted the competent Province of Bolzano to take action. The eight-metre-wide underpass has been equipped with stationary side rails, and an additional vertical support post will be mounted when the time comes to assemble the barriers. Municipal road service workers have already practised installing and locking into place the 25 or so barrier sections, which are fitted with seals.

Conclusion: Thanks to the speed and ease with which they can be installed, BLOBEL barriers offer effective protection against flood water. The plan is to get neighbouring communities along the Bahnstrasse to follow suit, so that their underpasses also receive the same level of flood protection and thus safeguard the various localities.